Native Connectors & Transceivers for Multi-Core Fiber (MCF): Where Things Stand Now

- Nguyen Tran Tien

- Sep 17, 2025

- 2 min read

“Native” building blocks for MCF—i.e., connectors and transceivers that mate directly to the multi-core geometry instead of relying on external fan-in/fan-out (FIFO) pigtails—have moved from lab curiosities to credible prototypes and early demos. Japan’s NTT and Sumitomo Electric established the connector foundations (LC/MU/SC and MT/MPO styles adapted to MCF) and proved low-loss, physical-contact mating. More recently, Hyper Photonix showed an 800G pluggable with an embedded FIFO micro-assembly inside the module, enabling direct MCF connectivity at the transceiver face—a practical near-term “native” approach for data-center form factors.

What “native” really means (and why it matters)

Traditionally, MCF links are terminated using external FIFO devices that map each MCF core to separate single-core fibers and standard connectors. It works—but adds cost, bulk, insertion loss, and operational complexity. “Native” components instead align to the actual core layout of the MCF at the interface, either by (a) adapting the connector mechanics (rotation/PC contact over off-center cores) or (b) integrating the fan-in/out function into the transceiver package so you plug MCF straight into the module. Both roads cut boxes in the path and simplify deployment.

Native connector tech: from principle to practical parts

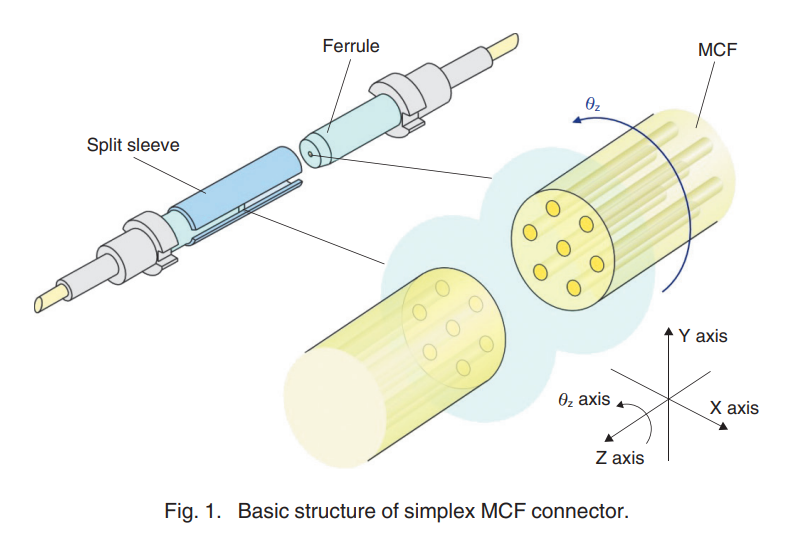

Key challenges for an MCF connector are rotational alignment (cores are off-axis, so clocking matters) and achieving true physical contact (PC) across all cores with reasonable mating force. NTT’s program tackled this in 2015–2017 with simplex and multi-MCF connectors that constrain rotation and use MT-style ferrules; they reported <0.2–0.3 dB average IL and >45 dB return loss—on par with single-core practice.

Sumitomo Electric extended this into highly practical shapes—LC, MU, SC for single-MCF and MT/MPO for multi-MCF—adding an Oldham-coupling mechanism to allow ferrule “float” without sacrificing tight rotational tolerance. They also developed MCF-optimized end-face polishing (flatter facet curvature) so PC contact is achieved on outer cores at standard mating forces. In OFC 2018 results (paper reposted 2025), they showed LC/MU/SC connectors with <0.5 dB IL across all cores using standard 125 µm MCF.

Native transceivers: from co-design silicon photonics to pluggable demos

In 2025, Hyper Photonix announced an 800G pluggable that embeds the FIFO micro-assembly inside the transceiver module, eliminating the separate external FI/FO box. The company demonstrated direct connectivity to Fujikura MCF at OFC’25 and disclosed a roadmap to 1.6T/3.2T. While the fan-in/out function still exists, integrating it inside the module is a pragmatic step toward “native” fieldability in standard QSFP-DD/OSFP ecosystems.

References & further reading

NTT: Low-loss physical-contact MCF connectors (simplex and multi-MCF) and pluggable FIFO concepts; measured IL/RL and rotation control methods. NTT Review

Sumitomo Electric (OFC 2018): LC/MU/SC native MCF and MCF-MPO/MT connector designs; Oldham coupling; MCF-optimized polishing; 96-ch/256-core demonstrations. Sumitomo Electric

Sumitomo Electric + Luxtera (ECOC 2017): 200 Gb/s silicon photonics transceiver natively supporting MCF—no external FIFO; comparable link performance to SMF. Sumitomo Electric

Hyper Photonix (OFC 2025): 800G pluggable for MCF with embedded FIFO micro-assembly, enabling direct MCF connectivity and a roadmap to 1.6T/3.2T. Business Wire

EXAT/Chiba Institute (2024): Connector mechanics for coupled-MCF (keyway/float constraints, angle precision). ITU-AJ - The ITU Association of Japan

Comments